Press Checking WMB 3D #3 Collector’s Print Edition

If you’ve ever held a copy of WMB 3D: World’s Most Beautiful in your hand, you know it’s a beast of a publication. With 2D and 3D sides combined, the magazine measure over 1/2 inch thick, and boasts over 225 pages: each one meticulously photographed, retouched, and designed by our art team. As such, I don’t like leaving the printing up to chance.

After years of seeing my work printed for other publications, one of the printers that always delivered stellar results was Canadian print-house Lowe-Martin (formerly Dollco). For this reason, I chose them as the official printer of WMB 3D. When I received the first shipment of Issue 1 in 2011, I couldn’t believe I was looking at CMYK printing—the colors were nearly as rich as they were on an RGB display. For Issue 3, I decided to make the trip to visit our friends in Ontario, and document the process for you. (Be warned: I’m going to get technical, so the faint of heart should just skip to the pretty pictures now.)

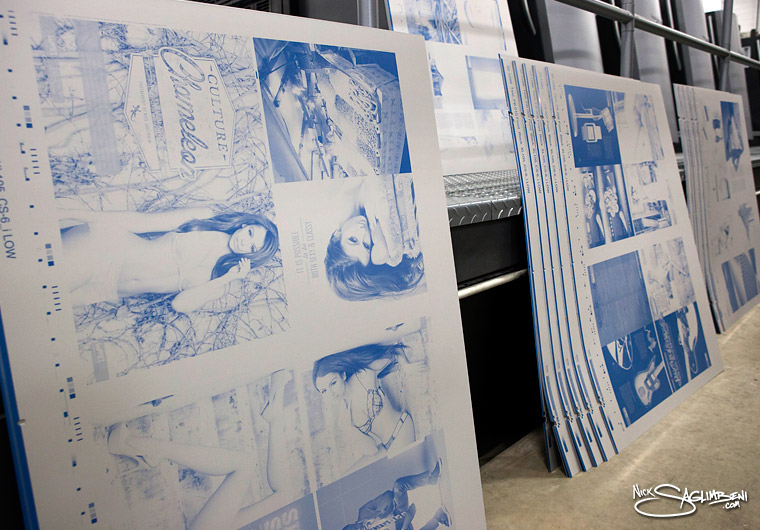

After we locked the layout for the publication, the master PDFs were generated and sent to the printer via FTP. Once the images are cleared through preflight—file prep which insures color and registration accuracy—a high-resolution set of color-match proofs was sent to me in Los Angeles to review. Upon approval, color-separation ink plates are burned (at a microscopic 20 micron resolution) and mounted onto press for printing.

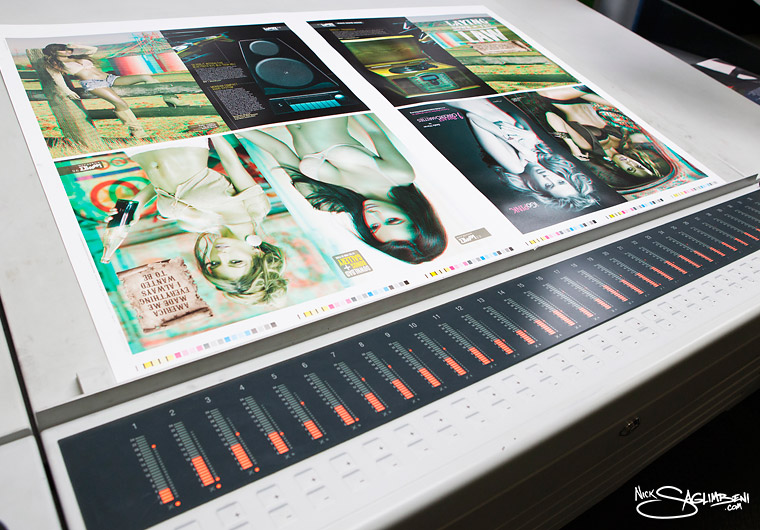

Issue 3 was printed on a brand-new Heidelberg XL 40″ 10-color press. In the case of WMB, five ink bays are reserved for one side of the page (typically Cyan, Magenta, Yellow, Black, and then a spot-color or varnish), after which the page is perfected (flipped in line) and the back side is run through the next five ink bays.

The pressman color matches individual ink densities using the Inpress control sheet reader. Once approved, the switch is thrown and the sheets are printed en masse. The Estella-Warren-graced cover was then run though press a second time to apply the spot gloss varnish to the WMB logo and to Estella’s boots, making them extra spiffy. Finally, the images are collated, bound, glued and trimmed on a perfect binder, where they are made retail-ready.

My thanks to the stellar team at Lowe-Martin for taking such wonderful care of our progressive publication: Pam, Dave, Brad, Cathy, Paul, Noah, Rose, Rob, April and the rest of the team. To see this beautifully printed book up close, visit the Slickforce Store to order your copy of WMB 3D Issue 3.

You must be logged in to post a comment.